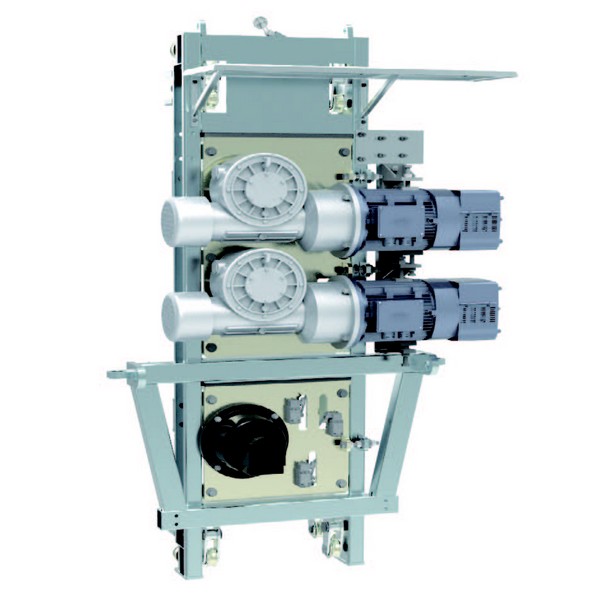

Man and material hoist with dual electrical control

Elevate Your Construction Efficiency with man and material hoist

Feature

Efficiency

It facilitates the vertical movement of personnel and materials, enhancing productivity on construction sites.

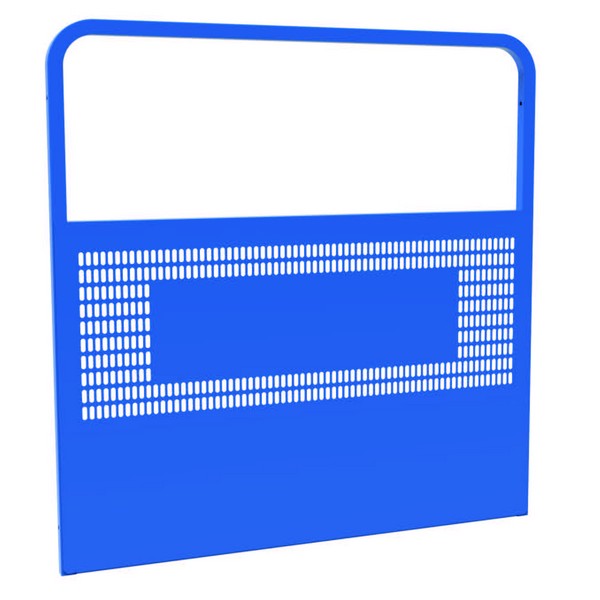

Safety

With robust safety features and adherence to regulations, it ensures the secure transportation of goods and workers, minimizing the risk of accidents.

Versatility

Suitable for a range of construction projects, from mid to high-rise buildings, it adapts to various site requirements.

Control

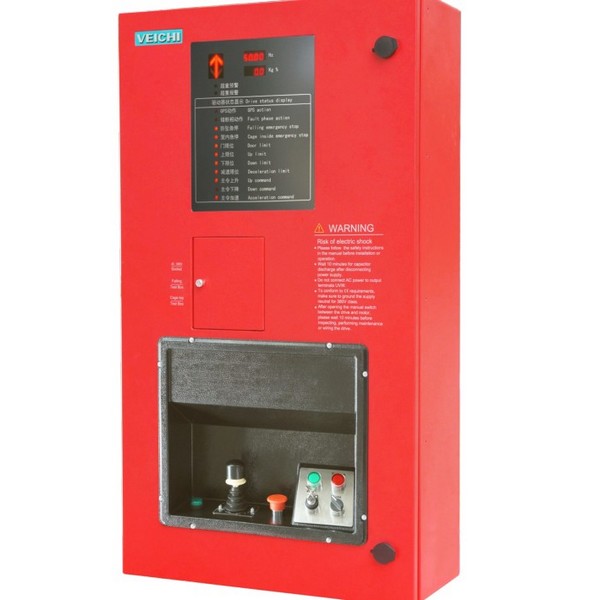

Dual electrical control allows for easy and precise operation from both the cage and ground level, enhancing usability and efficiency.

Speed

Operating at speeds of 0-24m/min, it provides swift vertical transportation, contributing to project timelines and deadlines.

Reliability

Designed for durability and longevity, it withstands the rigors of construction site usage, offering dependable performance throughout the project duration.

Cost-effectiveness

By streamlining material handling processes and improving workflow, it helps optimize resource utilization and reduce project costs over time.

Application

Transporting Materials: Material hoists are primarily used for vertically transporting construction materials such as bricks, concrete, steel beams, and other heavy items to different floors of a building under construction. This facilitates efficient material handling and reduces the need for manual labor.

Moving Equipment and Tools: Apart from materials, hoists can also be used to transport construction equipment, tools, and machinery to elevated work areas, saving time and effort.

Personnel Transportation: Material hoists are often equipped with a cage or platform that can accommodate workers, allowing them to travel safely and quickly between different levels of a construction site. This enhances worker mobility and improves overall efficiency.

Construction Site Access: In addition to transporting materials and personnel within a building, hoists can also provide access to different levels of the construction site itself, enabling workers to reach elevated areas such as scaffolding or rooftop work zones.

Debris Removal: Material hoists can be used to remove construction debris and waste from upper floors, streamlining the cleanup process and maintaining a safer and more organized work environment.

Maintenance and Renovation: Material hoists are not only useful during initial construction but also during maintenance or renovation projects, where they can facilitate the movement of materials, equipment, and personnel to different levels of an existing structure.

Features

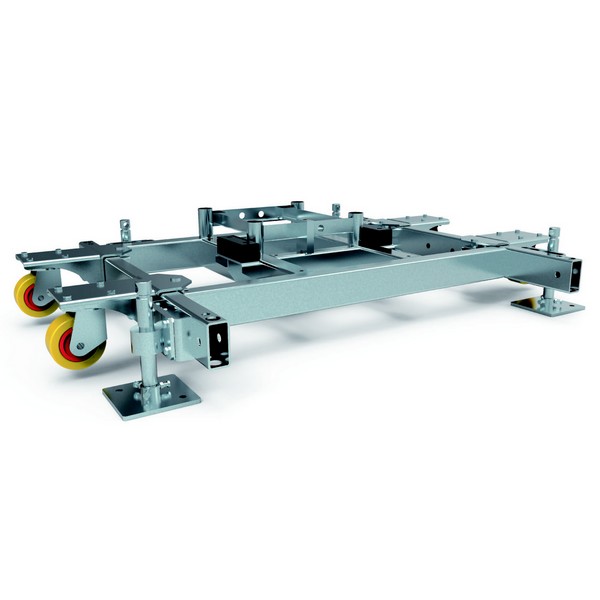

Parameter

| Model | MH75 | MH100 | MH150 | MH200 |

| Rated capacity | 750kg | 1000kg | 1500kg | 2000kg |

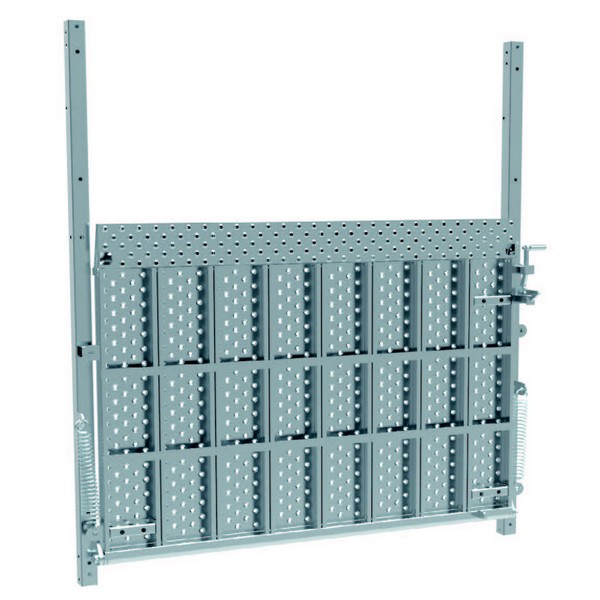

| Type of mast | 450*450*1508mm | 450*450*1508mm | 450*450*1508mm | 450*450*1508mm |

| Rack modules | 5 | 5 | 5 | 5 |

| Max lifting height | 150m | 150m | 150m | 150m |

| Max tie distance | 6m | 6m | 6m | 6m |

| Max overhanging | 4.5m | 4.5m | 4.5m | 4.5m |

| Power supply | 380/220V 50/60Hz, 3P | 380/220V 50/60Hz, 3P | 380/220V 50/60Hz, 3P | 380/220V 50/60Hz, 3P |