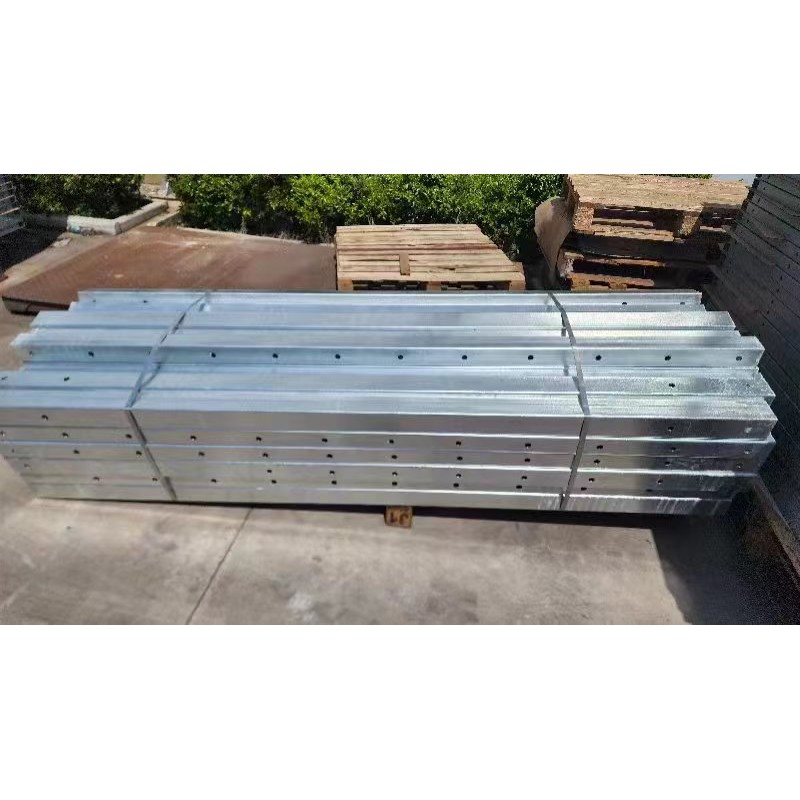

Suspension platform with serew-nut connection

Introduction

When it comes to the installation methods of suspended platforms, there are two primary options: pin-and-hole connection and screw-nut connection. Each method offers distinct advantages and disadvantages that cater to different needs and preferences.

The screw-nut connection is an economical and widely used choice. Its primary strength lies in its commonality and accessibility, as standard components are easily available for purchase. This approach offers cost-efficiency and simplicity, making it a popular choice for a broad range of applications.

On the other hand, the pin-and-hole connection is highly preferred in the European market due to its convenience and speed of installation. This method allows for quick assembly and disassembly, significantly reducing the installation time. However, it demands high precision in the pin and platform components, and the additional accessories required increase the overall cost. This results in a higher price tag compared to the screw-nut connection.

In summary, the screw-nut connection offers a cost-effective and widely available solution, while the pin-and-hole connection provides a rapid installation process that is favored in the European market, albeit with a higher cost. The choice between the two ultimately depends on the specific requirements and preferences of the user.

Parameter

| Item | ZLP630 | ZLP800 | ||

| Rated capacity | 630 kg | 800 kg | ||

| Rated speed | 9-11 m/min | 9-11 m/min | ||

| Max. platform length | 6 m | 7.5m | ||

| Galvanized steel rope | Structure | 4×31SW+FC | 4×31SW+FC | |

| Diameter | 8.3 mm | 8.6 mm | ||

| Rated strength | 2160 MPa | 2160 MPa | ||

| Breaking force | More than 54 kN | More than 54 kN | ||

| Hoist | Hoist model | LTD6.3 | LTD8 | |

| Rated lifting force | 6.17 kN | 8 kN | ||

| Motor | Model | YEJ 90L-4 | YEJ 90L-4 | |

| Power | 1.5 kW | 1.8 kW | ||

| Voltage | 3N~380 V | 3N~380 V | ||

| Speed | 1420 r/min | 1420 r/min | ||

| Brake force moment | 15 N·m | 15 N·m | ||

| Suspension mechanism | Front beam overhang | 1.3 m | 1.3 m | |

| Height adjustment | 1.365~1.925 m | 1.365~1.925 m | ||

| Counter weight | 900 kg | 1000 kg | ||

Parts Display